Exploring the Types of Thermoplastics Used in Medical Device Manufacturing. In the realm of medical device manufacturing, the choice of materials is crucial for ensuring the safety, efficacy, and durability of the final products. Thermoplastics have emerged as…

Understanding Elastomers and Their Role in Medical Device Manufacturing. In the world of medical devices, materials play a crucial role in ensuring the safety, efficacy, and durability of the products. Among these materials, elastomers stand out due to their unique properties…

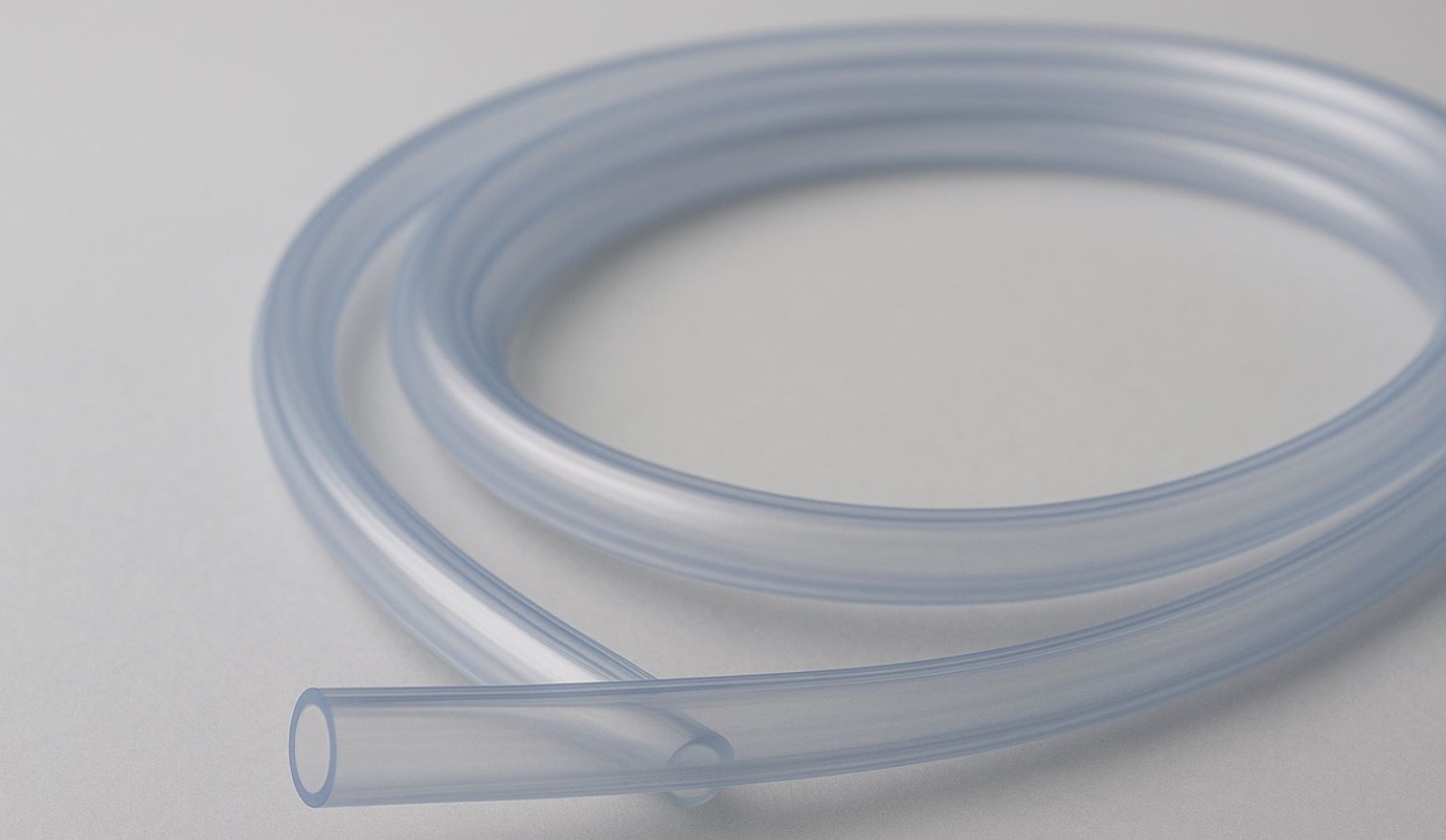

Polyvinyl chloride (PVC) has been a cornerstone in the medical device industry for over 60 years. Its unique properties make it an ideal material for a wide range of medical applications, particularly in the manufacturing of medical tubing. PVC is a synthetic plastic polymer…

Injection moulding is a cornerstone of modern manufacturing, particularly in the medical device industry. This versatile process enables the production of complex, high-precision components that are essential for a variety of medical applications…

In the highly regulated world of medical device manufacturing, maintaining a controlled environment is not just a best practice – it is a necessity. One of the most critical tools for achieving this is the cleanroom. Cleanrooms are specialised environ…

In the ever-evolving landscape of medical device manufacturing, extrusion is a key process. This technique is integral to producing a variety of plastic medical components. Let’s explore what extrusion involves, how it works, and why it is important i…PROMEPLA BLOG

ARTICLES

Thermoplastics in Medical Device Manufacturing

Elastomers in Medical Device Manufacturing

Use of PVC for Medical Tubing Manufacturing

Injection Moulding Process in Medical Device Manufacturing

Cleanrooms: Key to Medical Components Manufacturing

Extrusion Process in Medical Device Manufacturing