Use of PVC for Medical Tubing Manufacturing

Why PVC is a Preferred Material for Medical Tubing Manufacturing

Polyvinyl chloride (PVC) has been a cornerstone in the medical device industry for over 60 years. Its unique properties make it an ideal material for a wide range of medical applications, particularly in the manufacturing of medical tubing.

What is PVC?

PVC is a synthetic plastic polymer made from the polymerisation of vinyl chloride. It is one of the most versatile and widely used plastics in the world. PVC can be formulated to be either rigid or flexible, making it suitable for a variety of applications. In its flexible form, PVC is used extensively in the medical field, particularly for medical tubing.

Key Properties of PVC

There are several key properties that make PVC an excellent choice for medical tubing:

- Flexibility and Durability: PVC can be made highly flexible by adding plasticisers. This flexibility is crucial for medical tubing, as it needs to bend and move without kinking or breaking. Despite this flexibility, PVC remains durable and can withstand the rigours of medical use.

- Biocompatibility: PVC is biocompatible, meaning it does not cause adverse reactions when in contact with human tissues. This is essential for medical devices that come into direct contact with the body, such as intravenous (IV) lines and catheters.

- Chemical Resistance: PVC is resistant to a wide range of chemicals, including acids, alkalis, and various solvents. This chemical stability ensures that the tubing does not degrade or react with the fluids it transports, thereby maintaining the integrity of medical treatments.

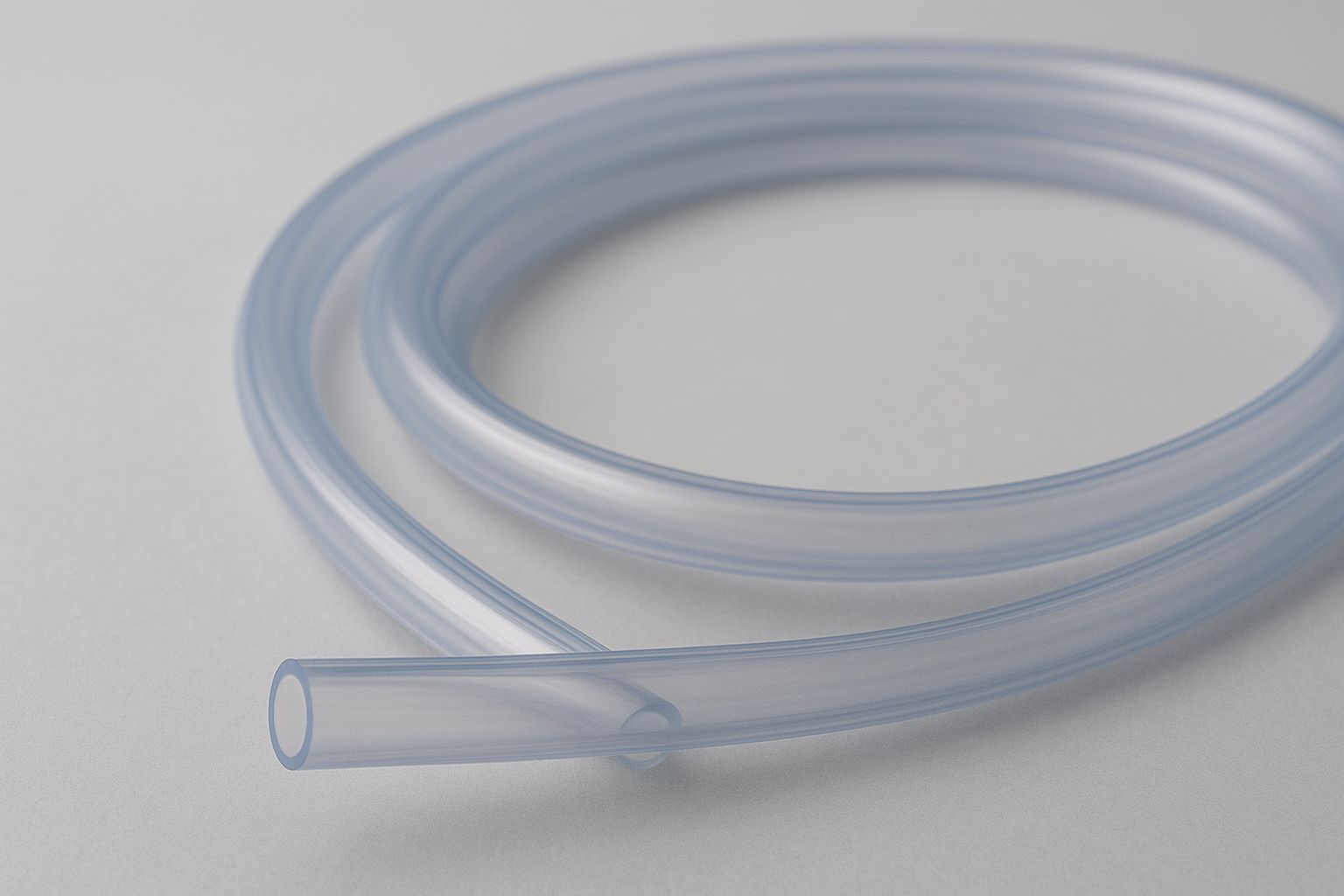

- Clarity and Transparency: Flexible PVC can be made transparent, allowing healthcare professionals to easily monitor the flow of fluids through the tubing. This visibility is critical for ensuring proper administration of medications and fluids.

- Ease of Sterilisation: PVC can be sterilised using various methods, including autoclaving, gamma radiation, and ethylene oxide. This versatility in sterilisation ensures that PVC medical tubing can be kept sterile and safe for use in medical environments.

- Cost-Effectiveness: PVC is relatively inexpensive compared to other materials used in medical device manufacturing. Its affordability makes it an attractive option for producing disposable medical devices, which need to be cost-effective while maintaining high quality.

Applications of PVC in Medical Tubing

PVC’s unique properties make it suitable for a wide range of medical tubing applications:

- Intravenous (IV) Lines: PVC is commonly used to manufacture IV lines due to its flexibility, clarity, and biocompatibility. These lines are essential for the direct administration of fluids, medications, and nutrients into a patient’s bloodstream.

- Catheters: PVC catheters are used in various medical procedures, including urinary catheterisation and cardiac catheterisation. The flexibility and durability of PVC ensure that these devices can be safely and effectively used within the body.

- Respiratory Tubing: PVC is used to produce respiratory tubing for ventilators and other respiratory equipment. The material’s flexibility and chemical resistance make it ideal for delivering oxygen and other gases to patients.

- Blood Bags and Tubing: PVC is used in the production of blood bags and the associated tubing. The material’s chemical stability ensures that blood and other fluids can be safely stored and transported without contamination.

- Suction Tubes: PVC suction tubes are used to remove fluids from the body during surgical procedures. The flexibility and durability of PVC make it suitable for these critical applications.

Advantages of Using PVC in Medical Tubing

The use of PVC in medical tubing offers several advantages:

- Versatility: PVC can be easily extruded into various sizes, allowing for the production of customised medical tubing that meets specific patient needs.

- Reliability: PVC’s durability and chemical resistance ensure that medical tubing remains reliable and effective throughout its use.

- Safety: The biocompatibility and ease of sterilisation of PVC ensure that medical tubing is safe for use in a wide range of medical applications.

- Affordability: The cost-effectiveness of PVC makes it an attractive option for producing high-quality, disposable medical devices.

PVC’s unique combination of flexibility, durability, biocompatibility, chemical resistance, and cost-effectiveness makes it an ideal material for medical tubing manufacturing. Its widespread use in the medical field is a testament to its suitability for a variety of critical applications. At Medical Tubing, we specialise in the extrusion of PVC and other materials. Please do not hesitate to contact us for further information about medical tubing.